Balloon Tacking / Welding – Zeus FluoroPEELZ™ heat shrink provides an excellent means for welding balloons to dilation or drug delivery catheters. FluoroPEELZ™ is a superior alternative to polyolefin heat shrink, is easier to remove, and is not prone to tearing or damaging the balloon upon removal. If you prefer laser heating for your heat shrink recovery, FluoroPEELZ™ can be pigmented for use with CO2 laser recovery.

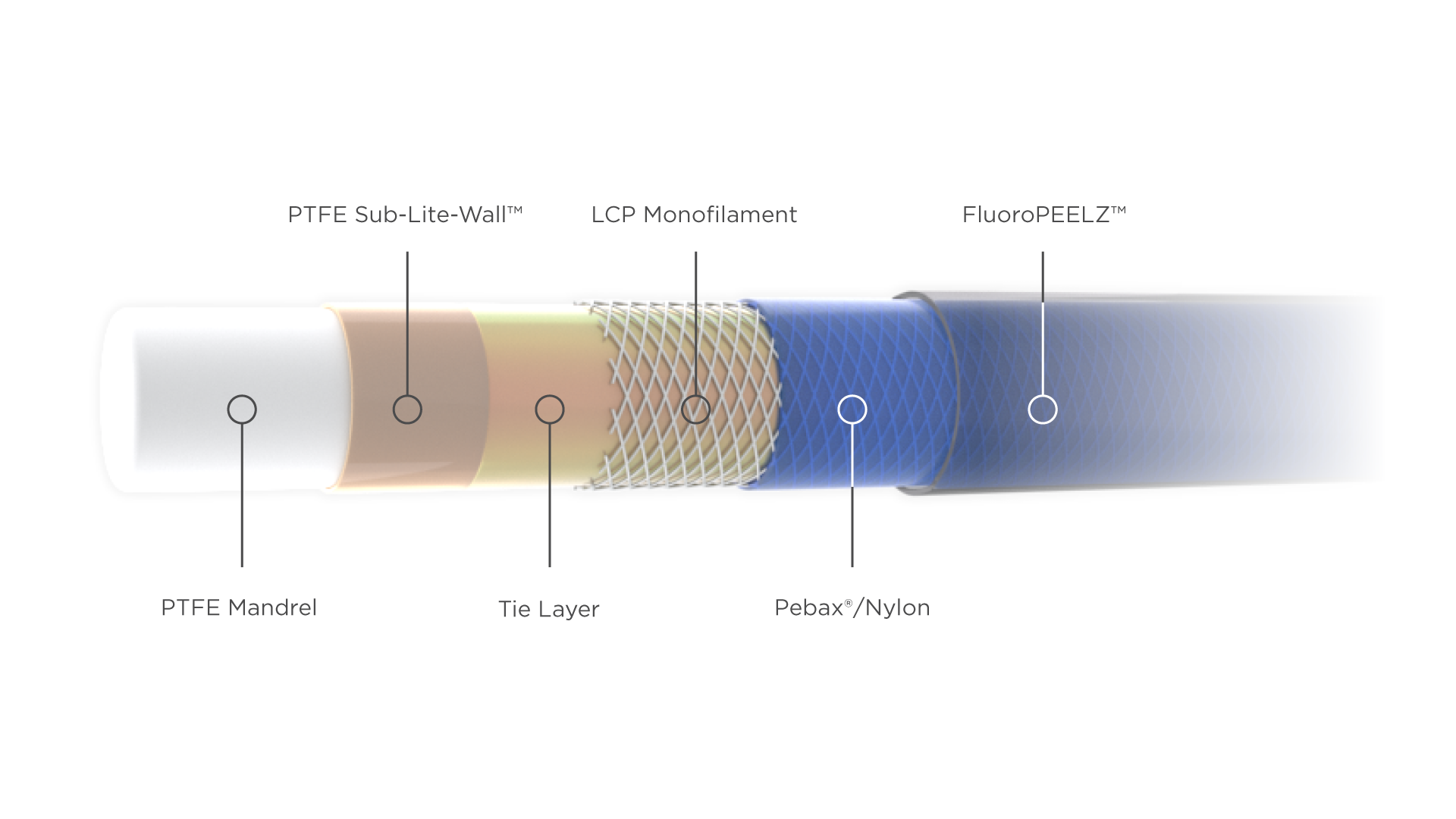

Catheter Construction – Used over nylon or Pebax® jacketing during catheter construction, Zeus FluoroPEELZ™ peelable heat shrink encapsulates the underlying jacketing while heat is applied to the outer FluoroPEELZ™ layer. The applied heat also melts the underlying jacketing material, allowing the jacket to reflow into the catheter braiding, thus bonding the catheter base liner, braiding, and jacketing together. Once the jacket material has cured, the recovered FluoroPEELZ™ top layer is removed, beginning with the FluoroPEELZ™ slit fixture.

Packaging / Balloon and Stent Protectors – As non-heat shrinkable extruded tubing, FluoroPEELZ™ is also available for use as packaging aids to protect catheter balloons, stents, or balloon-stent assemblies during the manufacturing process. Balloon and stent assemblies are held securely and protected within the FluoroPEELZ™ encapsulation until they are ready for use.