Capabilities

We leverage the latest technologies, equipment, processing techniques, and materials to manufacture complex components, assemblies, and devices.

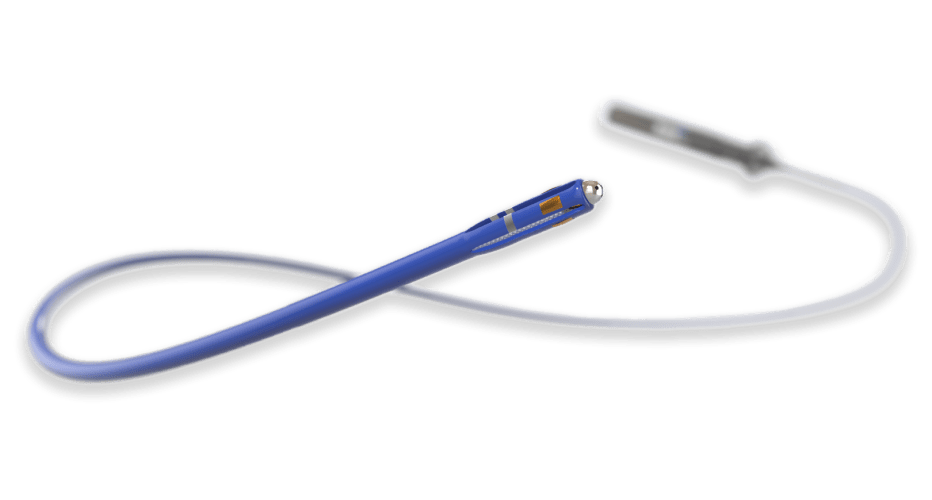

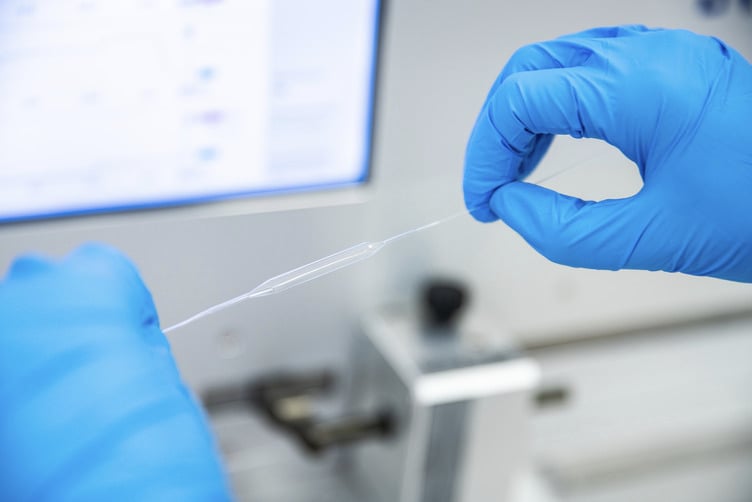

Complex Catheter Assembly

Custom catheter manufacturing assembly processes are performed in-house within ISO 13485:2016 certified cleanrooms.

- Capabilities from Microcatheters to Structural Heart

- Coil Reinforced Shafts

- Multiple Durometer Shafts

- Multi-Lumen Shafts

- Deflection/Articulation Shafts

- Electrophysiology Catheters

We assemble catheters utilizing a combination of manual, semi-automated, and automated processes, all validated to ensure robust reliability and repeatability.

Our modern ISO 13485:2016 compliant Quality System and highly trained cleanroom product builders ensure full compliance across all components and assemblies.

View projects

“Their drive to understand our design needs and develop flexible manufacturing solutions is key to our NPI success.”

OEM – Structural Heart

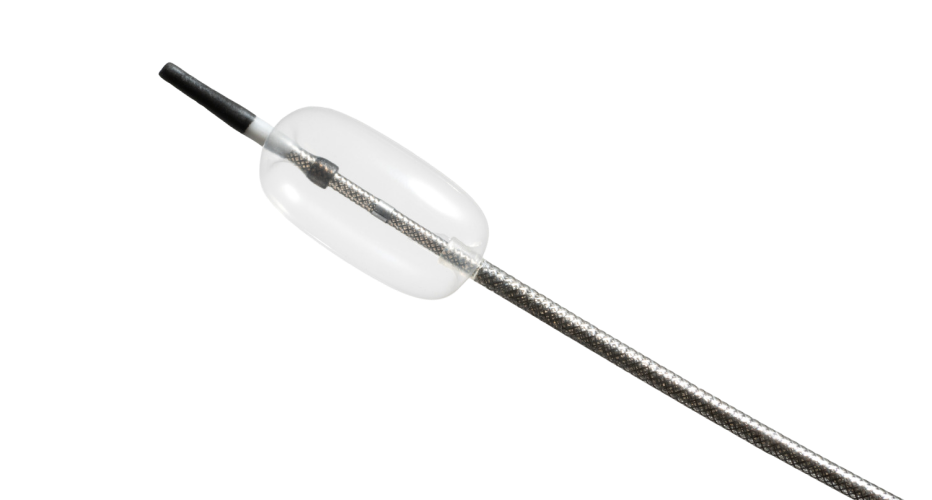

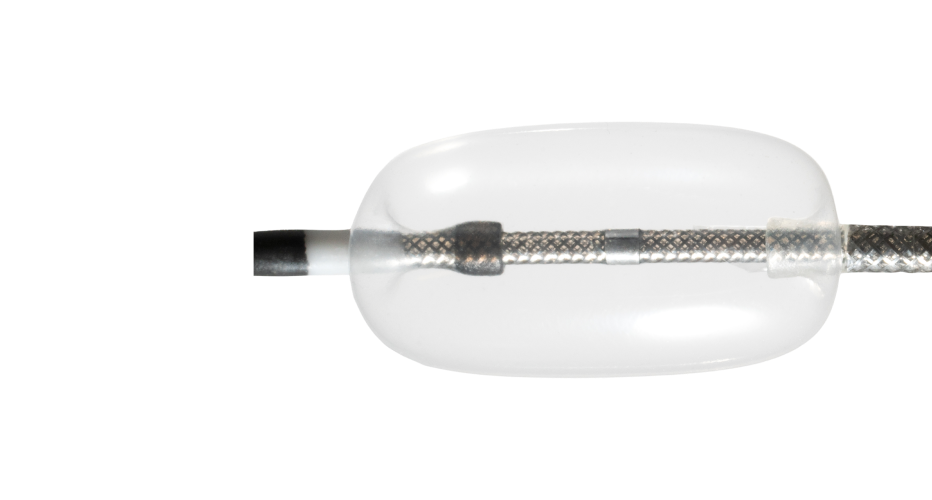

Balloons & Balloon Catheters

Our engineering expertise, balloon tubing capabilities, and materials science knowledge enable us to deliver highly customized balloon design and manufacturing solutions.

- Balloon Catheter Systems as small as .014″

- Custom Balloon Diameters range: 1.5mm to 25mm

- Custom Balloon Lengths range: 5mm to 250mm

- Compliant and Non-Compliant Balloon Materials

- Balloon Folding (3-6 fold)

- Stent Delivery Systems

Materials

- Pebax®

- Polyethylene

- Polyurethane

- Polyamide 12

- Chronoprene®

- Tecoflex®/Tecothane®

We leverage cutting-edge processing equipment and decades of problem-solving capabilities to help customers bring a product from concept to reality in the shortest possible time.

View projects

“A genuine and highly collaborative partner and a natural extension of our R&D and production team.”

OEM - Neurovascular

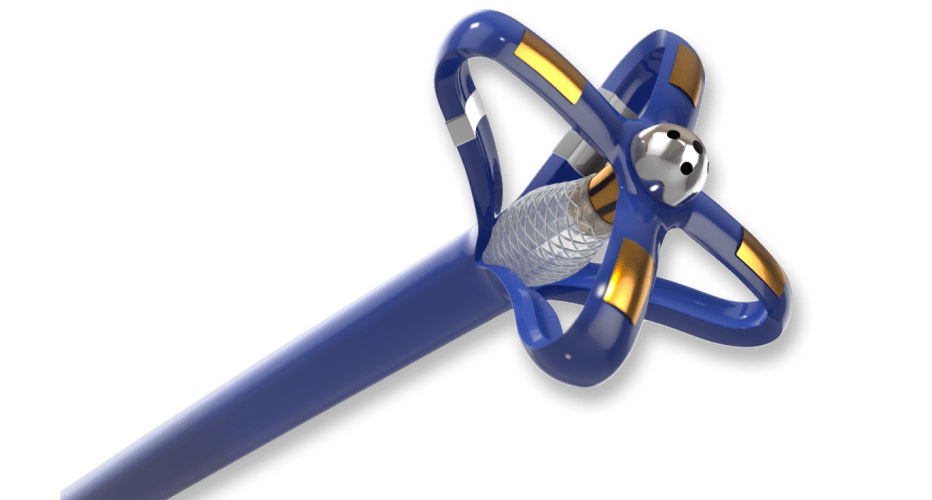

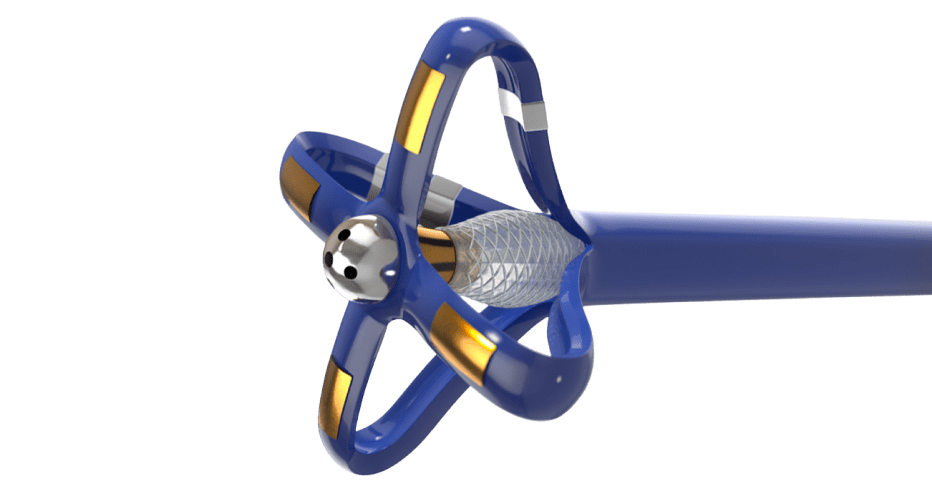

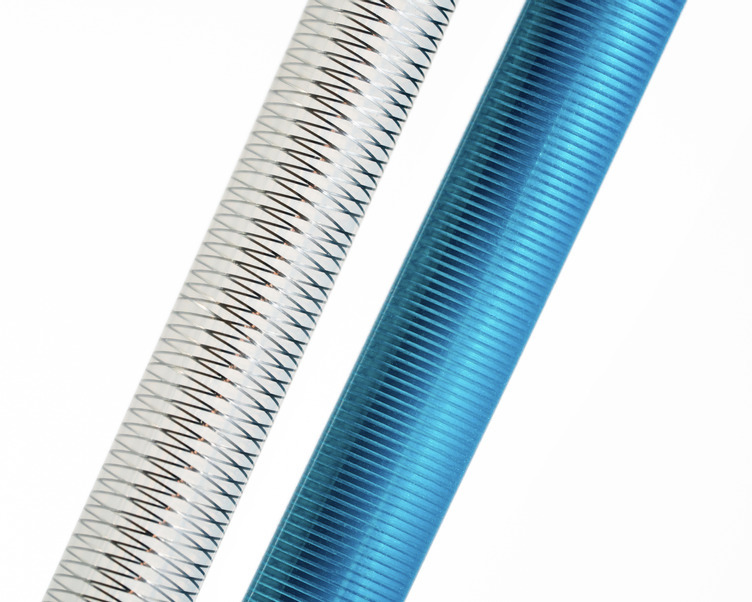

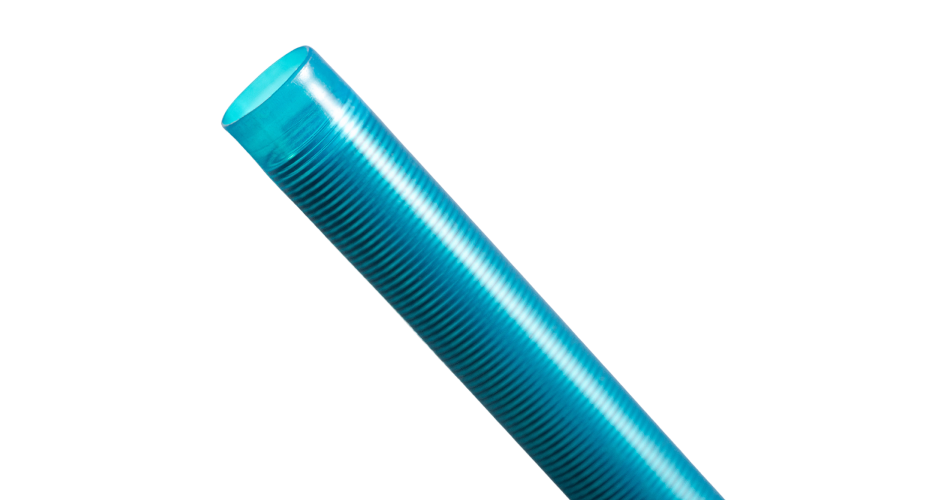

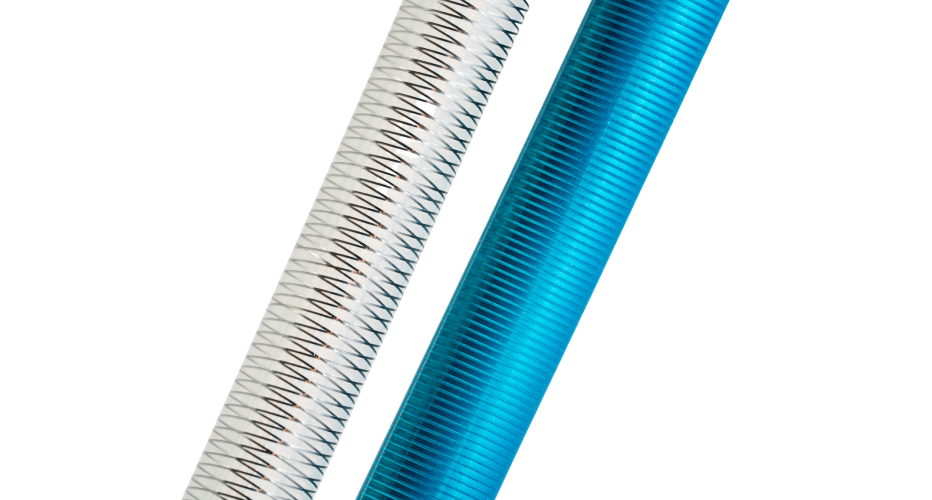

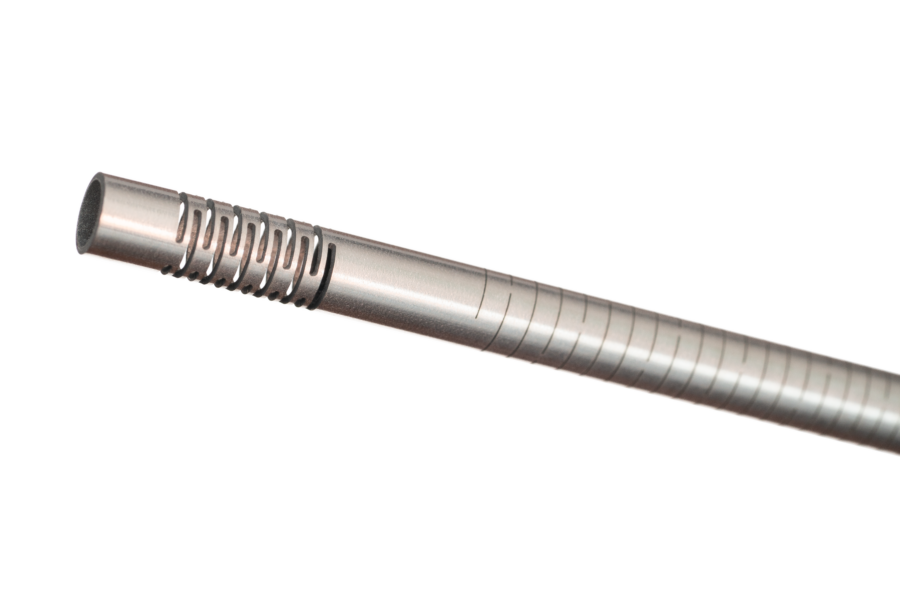

Braid & Coil Reinforced Shafts

We leverage our deep technical knowledge and proprietary processes to engineer ultra-thin walled braided and coiled catheter shafts.

- Sizing from 1.5F to 38F

- Metallic and Advanced Non-Metallic Materials

- Variable Pitch along Shaft

- 16 Carrier and 32 Carrier Braiding

- In-house Coil Winding Equipment

- Catheter Shaping and Thin Wall Construction (0.004″)

- Integrated Systems with Coils, Hypotubes, Braid, and Laser Cut Tubes

Our engineers continually push boundaries to deliver the optimal combination of crush strength, flexibility, kink resistance, control, and wall thickness.

Custom catheter shaft solutions that expand design options and enhance material and device performance, facilitating next-gen catheter designs.

View projects

“Using their proprietary process, they cost-effectively developed highly complex coil and braid reinforced shafts. True experts in catheter shaft technology.”

OEM

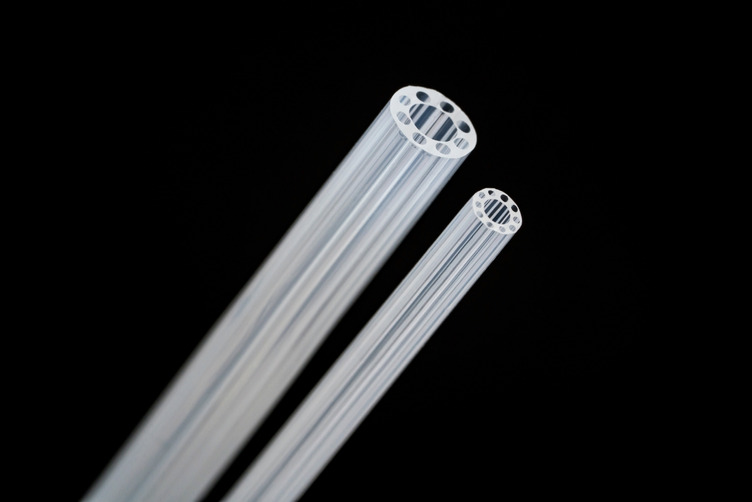

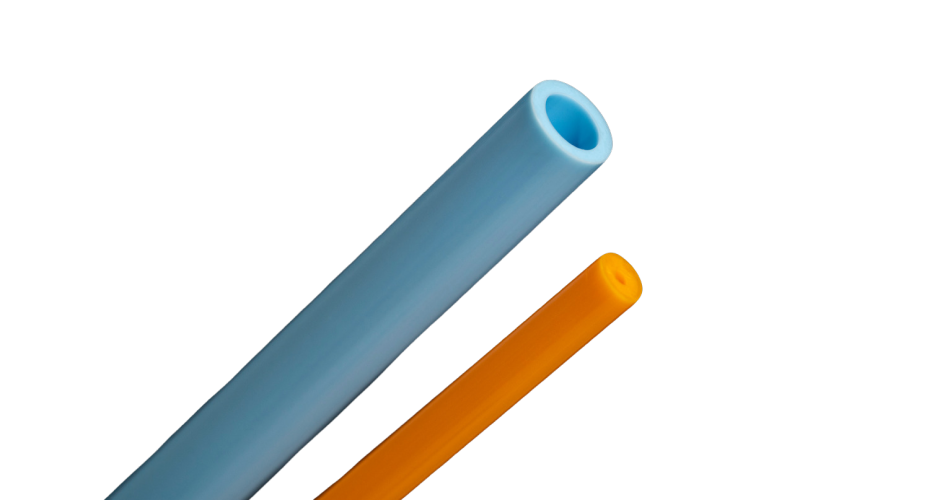

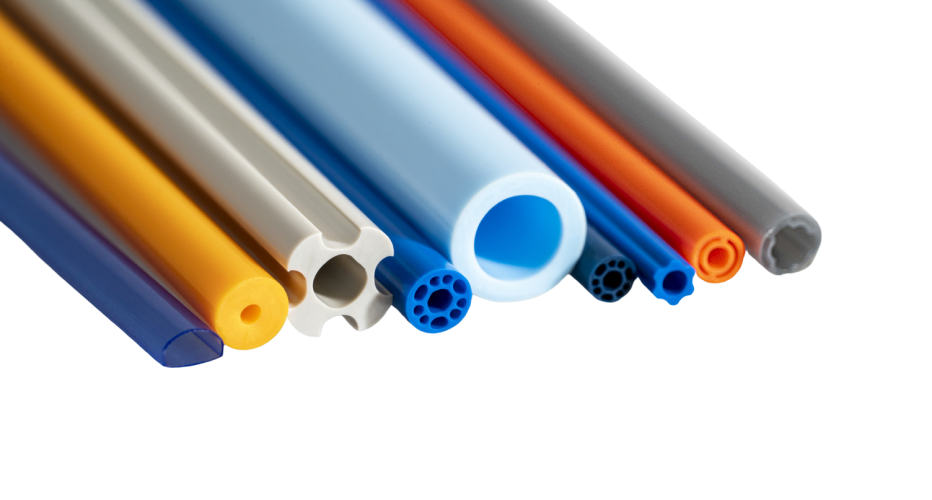

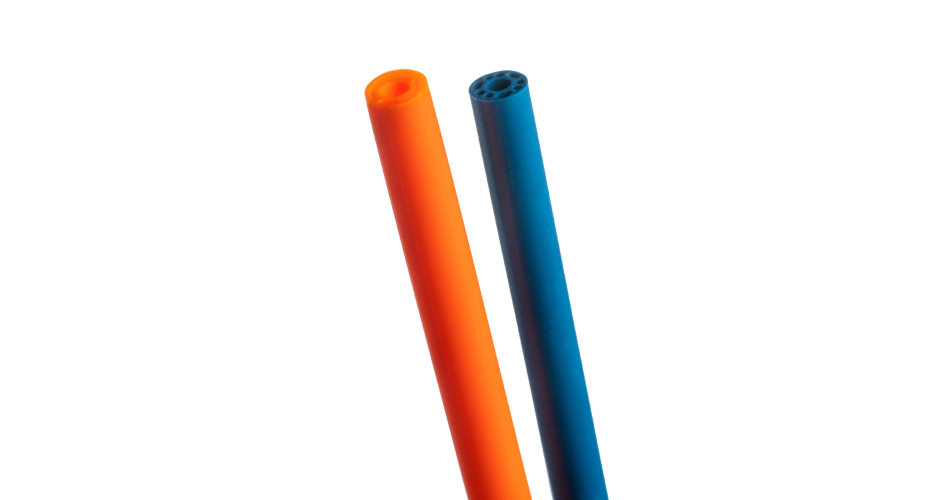

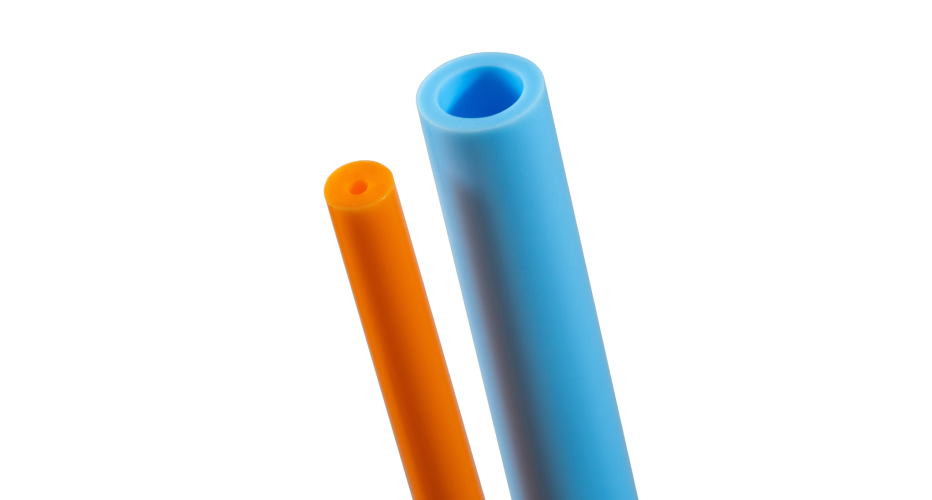

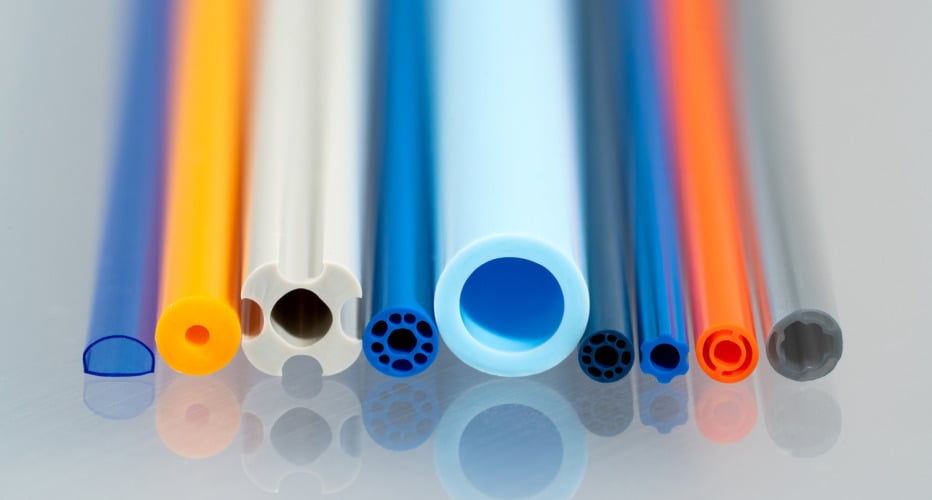

Extrusions

We design, develop and manufacture advanced extruded tubing and components to support complex catheter design and manufacturing requirements.

- Single Lumen, Multi-Lumen, Profile, and Monofilament

- Bump or Tapered Extrusion

- OD: 0.010” to 0.300’’ OD

- Wall: 0.001” to 0.075’’

- Length: 0.100” to Spools

- Tolerances: +/-0.0005”

Materials

- Pebax®, Nylon 11 & 12

- Polyethylene, Polypropylene, Polyurethane

- Implantable Grade Elastomers

- Radiopaque Fillers

- Lubricious Additives

Our state-of-the-art equipment allows us to hold tight tolerances enabling greater design possibilities for our customers.

High-performance tubing using the latest extrusion technologies, available at competitive lead times.

View projects

“Treating us as partners and not just another customer has helped accelerate our innovation and powered our growth.”

Med Tech Company

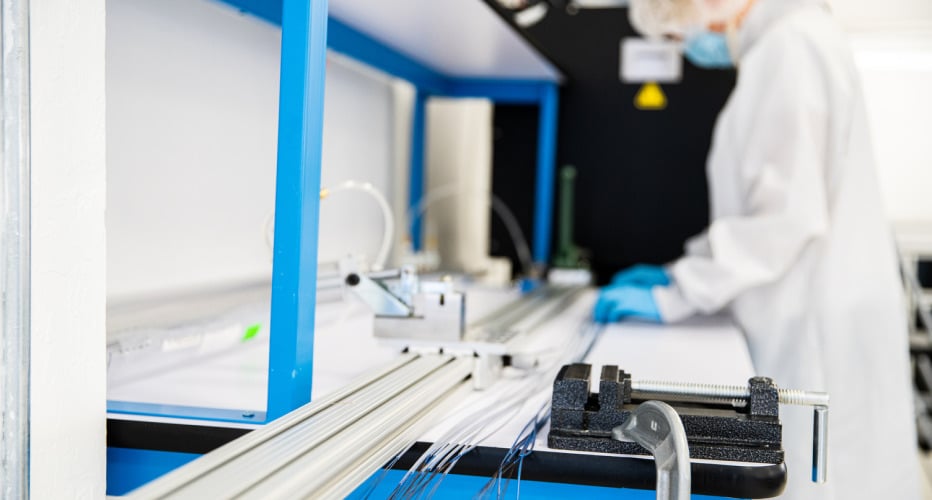

Laser Processing Center of Excellence

Advanced laser welding, cutting, and ablation processes are performed in-house at our Minnesota manufacturing facility.

- Laser Welding for wire and coil termination and pull ring assemblies for steerable catheters

- Laser Cutting for complex steerable catheters and custom flexibility profiles

- Laser Ablation for selective removal of metals and polymers

Materials

- Stainless Steel

- Nitinol

- Inconel

- Cobalt Chrome

- Platinum / Iridium

- Gold

- Tungsten

- Titanium

- Fluoropolymers (PTFE, FEP, PFA, etc.)

- Engineered Polymers (Pebax, PEEK, Polyimide)

- Implantable grade elastomers

Laser processing is high speed, high precision, and highly repeatable. Our state-of-the-art technology enables the precision processing of multiple metals and polymers across a wide range of devices.

View projects

“We came to them with a big ask, and they delivered. The expertise and creativity that they brought to this project was outstanding.”

OEM – Structural Heart